Your Playbook for Procuring Injection Molding Services from China

So, the big meeting just wrapped up. your new product has been approved, the timeline is aggressive, and funding is, to put it mildly, limited. Then a voice—perhaps your manager or the CFO—drops the line that gives every project manager a shock: “We should look at sourcing this from China.”

Naturally, you agree. On paper, it’s logical. The potential savings can be massive. However, your brain is racing with concerns. You know the rumors, don’t you? The quality disasters, the communication black holes, the shipment that shows up three months late looking nothing like the sample. It’s like balancing on a tightrope between a massive cost advantage and project disaster.

Here’s the thing, though. Sourcing China injection molding can be a calculated project. It’s a project, just like any other. And as with any project, success depends on your methodology. It’s less about finding the absolute cheapest quote and more about finding the right partner and managing the process with your eyes wide open. Disregard those scary tales. Let’s go through a step-by-step guide to succeed.

Initial Step: Prepare Your Information

Before searching suppliers or opening Alibaba, nail down your requirements. Honestly, more than half of all overseas manufacturing problems start right here, with a weak or incomplete information package. You can’t expect a factory on the other side of the world to read your mind. It’s akin to asking someone to price-build “a structure” with no details. You’ll get wildly varied quotes that are useless.

Aim to craft an RFQ package so precise and comprehensive it leaves no room for error. This package is your project’s foundation.

What should you include?

Begin with 3D CAD models. These are non-negotiable. Use standard formats such as STEP or IGS to ensure compatibility. This is the authoritative CAD geometry.

But 3D isn’t enough. You also need detailed 2D drawings. This is where you call out the stuff that a 3D model can’t communicate. I’m talking about critical tolerances (like ‘25.00±0.05 mm’), material specifications, required surface finishes, and notes on which features are absolutely critical to function. Any seal surfaces or critical hole sizes must be clearly labeled.

Next up, material. Don’t label it simply “Plastic.” Don’t even just say “ABS.” Get precise. If you need SABIC Cycolac MG38 in black, say exactly that. What’s the reason? Because resin grades number in the thousands. Specifying the exact resin grade ensures you get the strength, flexibility, UV resistance, and color consistency you planned for with what is plastic mold.

They can offer alternatives, but you must provide the initial spec.

Lastly, add your business data. What is your Estimated Annual Usage (EAU)? You must specify if it’s a 1K-part tool or a 1M-part production run. Cavity count, tooling cost, and per-unit pricing depend on volume.

Finding the Right Supplier

Okay, your RFQ package is a work of art. who will you target? The web is vast but overwhelming. Locating vendors is easy; vetting them is the real challenge.

Begin on popular marketplaces such as Alibaba or Made-in-China. They let you survey dozens of suppliers quickly. Use them to build a shortlist, not the final list. You’ll want to quickly build a list of maybe 10 to 15 companies that look promising.

But don’t stop there. Perhaps hire a local sourcing specialist. True, they charge a fee. Yet top agents deliver reliable, audited suppliers. They are your person on the ground, navigating the language and cultural barriers. As a newcomer, this offers priceless security. Consider it timeline insurance.

Another tactic: trade exhibitions. If you have the travel budget, attending a major industry event like Chinaplas can be a game-changer. In-person meetings trump emails. Inspect prototypes, interview engineers, and sense their capabilities. Also, leverage the tried-and-true referral network. Tap your professional contacts. Peer endorsements carry huge weight.

Shortlisting Serious Suppliers

After firing off that RFQ to a broad pool, the quotes will start trickling in. You’ll see ridiculously low offers and steep quotes. Now, sift through and shortlist 2–3 reliable candidates.

How to proceed? It involves both metrics and gut feel.

Begin with responsiveness. Are their replies prompt and clear? Do they communicate effectively in English? But here’s the real test: Are they asking you intelligent questions? Top vendors will critique and inquire. For instance: “Draft angle here could improve mold release. Tolerance check via CMM adds cost—proceed?” This is a massive green flag. It shows they’re engaged and experienced. Anyone who simply agrees to all specs is a red flag.

Afterward, verify their technical arsenal. Ask for a list of their equipment. Review examples of parts akin to your design. A small-gear shop won’t cut it for a big housing.

Next up: the factory audit. You can’t skip this. You would never hire a critical employee without an interview, so why would you send tens of thousands of dollars for a tool to a company you’ve never truly vetted? Either visit in person or engage a local audit service. They perform a one-day factory inspection. They will verify the company is real, check their quality certifications like ISO 9001, assess the condition of their machinery, and get a general feel for the operation. It’s the best few hundred dollars you will ever spend on your project.

Transforming CAD into Real Parts

After picking your vendor, you’ve negotiated the price and payment terms—a common structure is 50% of the tooling cost upfront to begin work, and the final 50% after you approve the first samples. Then comes the real action.

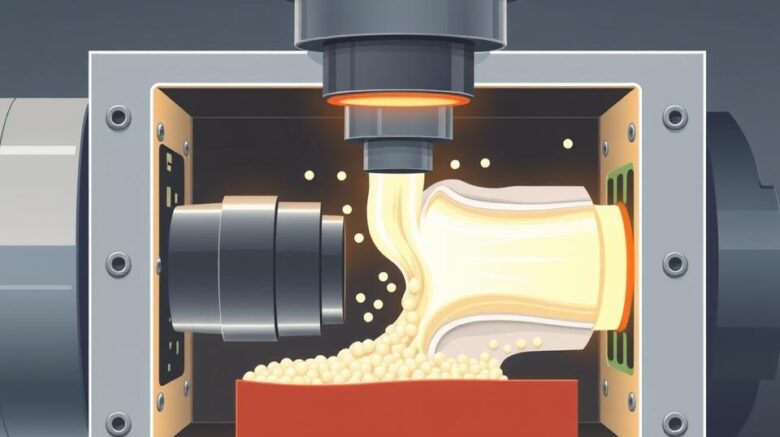

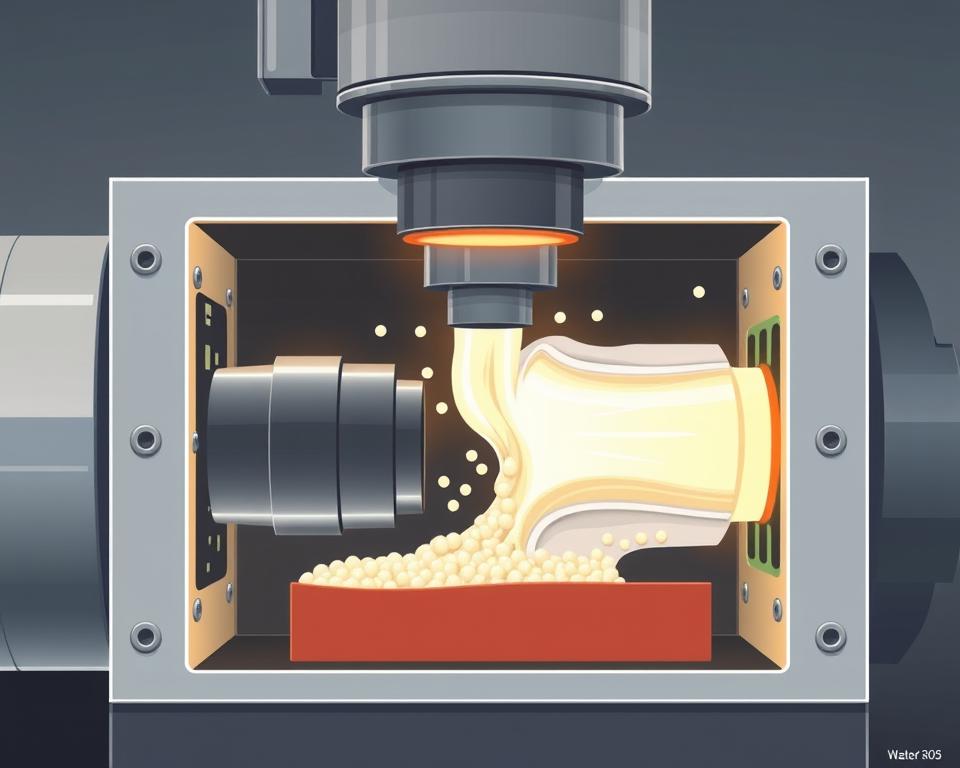

The first thing you should get back after sending your payment is a DFM report. Design for Manufacturability (DFM) is essential. It’s their professional review of your CAD. They’ll flag thick sections prone to sink, sharp edges that stress, or insufficient draft. A detailed DFM shows expertise. It’s a collaboration. You iterate with their team to optimize the mold.

When you greenlight the DFM, they machine the mold. Weeks on, you receive the thrilling “T1 samples shipped” notification. These represent the first trial parts. It’s your first real test.

Expect T1s to need tweaks. It’s par for the course. You’ll find minor defects, off-spec dimensions, or finish issues. You supply feedback, they tweak the tool, and T2 plastic mold samples follow. This process might take a couple of rounds. Plan for this loop in your schedule.

At last, you get the perfect shot. It meets every dimension, the finish is flawless, and it functions exactly as intended. This is your golden sample. You formally approve it, and this sample is now the standard against which all future mass-produced parts will be judged.

Completing the Sourcing Journey

Landing the golden sample is huge, yet the project continues. Next up: mass manufacturing. How do you ensure that the 10,000th part is just as good as the golden sample?

You need a clear Quality Control plan. Often, you hire a pre-shipment inspection service. Bring in an external QC firm. They’ll sample parts, check dimensions and finish versus your drawings and golden sample, and report. They’ll send you a detailed report with photos and measurements. Once you sign off, you greenlight shipping and the last payment. This simple step prevents you from receiving a container full of scrap metal.

Lastly, plan logistics. Understand the shipping terms, or Incoterms. Are you on FOB terms, where they load and you take over? Or is it EXW (Ex Works), where you are responsible for picking it up from their factory door? These details have a big impact on your final landed cost.

Overseas sourcing is a marathon. It relies on partnership-building. View them as allies, not vendors. Clear communication, mutual respect, and a solid process are your keys to success. No question, it’s demanding. But with this framework, it’s one you can absolutely nail, delivering the cost savings everyone wants without sacrificing your sanity—or the quality of your product. You’re ready.